High Altitude Solar Balloon Project: Year 1

This engineering project, funded by Dartmouth College, set the goal of building a high-altitude solar-heated ultra-lightweight balloon capable of lifting a 7 kg payload up to 100,000 ft above sea level. The project spanned two years, and in that time we made 8 prototype balloons ranging from 3 to 12 meters in diameter. The first year was dedicated to researching the components and materials to be used (see HASHBROWWN: materials).

In order to build a system that could fly at high altitudes for weeks or months without servicing, we had to use specialized materials that we trusted. The first half of this two-summer project involved the sourcing and testing of these materials. This involved analyzing the infrared opacity of energy-absorbing materials using a FLIR thermal imaging camera. These materials would be used for internal air-heating structures. The team also performed and plotted altitude appraisal for a cylindrical balloon's buoyancy given ambient and internal temperatures, volume, and weight using the 1976 Standard Atmosphere Calculator. Finding adhesive tapes that would hold the balloon together at the frigid stratospheric temperatures was another challenge. The team simulated these atmospheric temperatures through cryogenic treatments to assess each adhesive's feasibility. Below are some of the final materials we used in the balloons.

The Hunt for Absorption - We needed a material to absorb infrared radiation from the Sun and the Earth. This would produce the hot air required to lift the balloon. We experimented with dyes, pigments, spraypaints, chemical etchants, and various synthetic and organic textiles. The one constraint was material weight per area.

Thin Black Felt was determined to be the best material for absorbing infrared radiation from the Sun and the Earth.

6um Mylar Film was the main material used to construct our balloons. This roll was 1.5m in width and 3km in length!

12um Aluminized Mylar AKA "Space Blankets" were used to construct the insulating caps of the balloons. Their reflectivity minimized the heat radiated away from the hot body of air at the top of the balloon. This ensured longer flight times in suboptimal conditions (cloudy nights).

Carbon Fiber Rods were used to form skeletal rings around the bottom and top of the balloon. This forced the geometry of a cylinder with more volume than the natural balloon shape and allowed for easy attachment of the payload and hold-down lines.

Attaching Carbon Fiber Rods Early techniques used tightly wrapped string tied off and taped at both ends over a section of overlap between the rods (shown above). This technique was later replaced with heat-shrink tubing and connectors.

Heat Shrink Tubing was used to connect carbon fiber rods into sections of the balloons' skeletons.

These "Finger-trap" Connectors were used to rapidly assemble sections of the balloon's carbon fiber skeleton at the launch site. Originally designed for pigment tubing systems in the food industry, these "John Guest" style connectors fit our carbon fiber rods perfectly.

VHB Adhesive Transfer 1mil (3M) This adhesive transfer tape was used in the main construction of the balloons to attach the panels of Mylar along the seams. VHB tape is fully functional below -60°C, and is strongest at -30°C. These temperatures are not a possibility with most adhesive tapes.

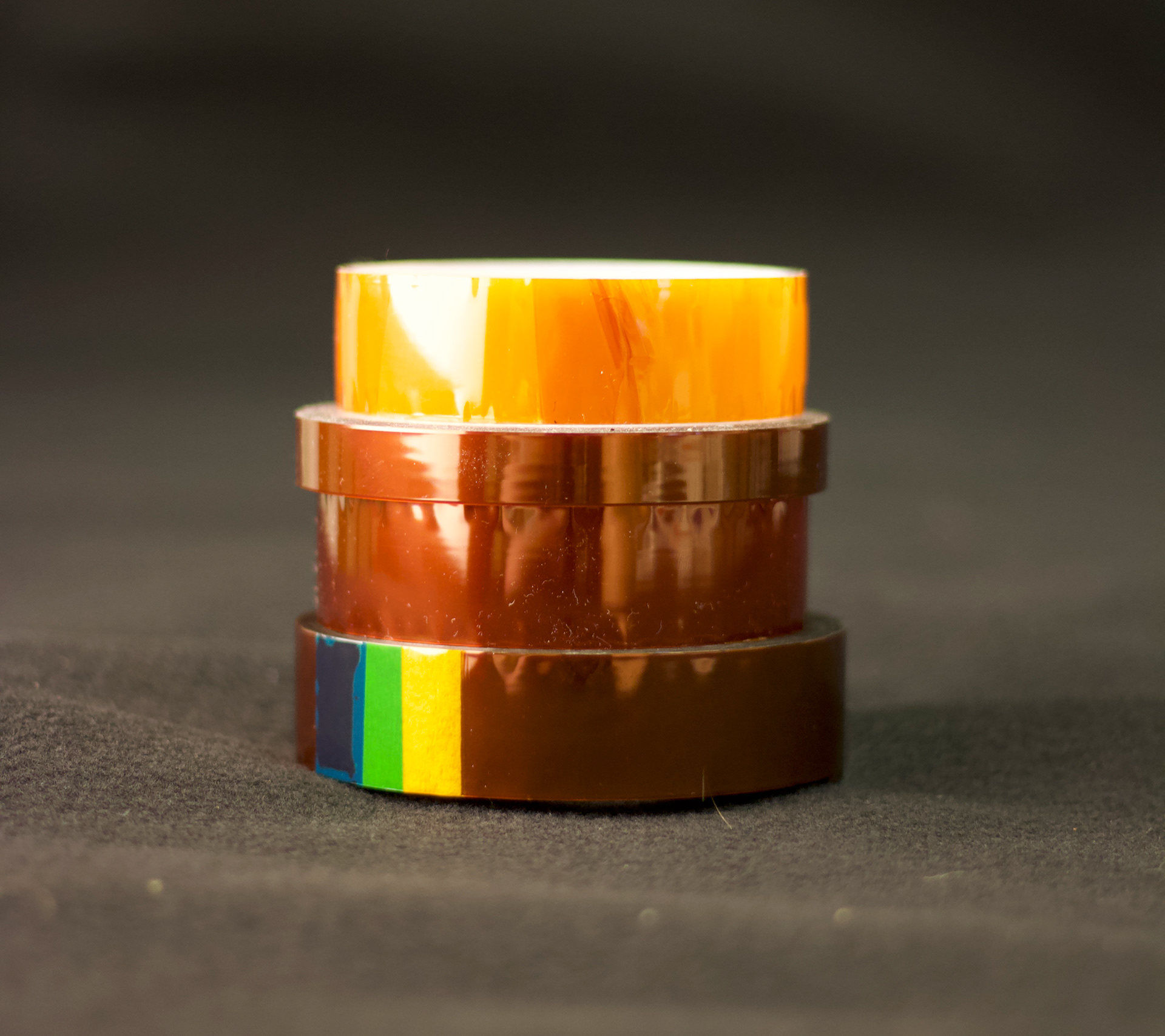

Kapton Tape 1mil (3M) Kapton is a polyimide film famous for its use in the aerospace industry. It was the reflective golden material wrapping the stage of the Apollo Lunar Module. We chose this tape because of its excellent performance at low temperatures and its relatively light weight.

850 Tape (3M) This tape was used in early prototypes for rip-stopping and puncture sealing. It was phased out by the later iterations as it had poor adhesion compared to Kapton tape.

Magnetic Tapes (3M) We experimented with these tapes during the vent design phase of the project. We needed a way to reseal the vents at the top of the balloon reliably and repeatably. Magnetic tapes were not immplimented in the final design, as they were only weakly magnetic and very heavy.

Velcro is relatively lightwieght and extremely resistant to shear slipping. Loops of velcro were used to attach the carbon fiber skeleton to the balloon quickly at the launch site while still allowing the skeletal rings to rotate and move freely. Before this freedom was implimented, balloons were tearing themselves apart in windy conditions when held down.

Kevlar, Dyneema, Spectra These lines were used to hold the payload, actuate the vent, and suspend the absorption material. They had to be strong, lightweight, and perform at temperatures below -60°C.

Carabiners, Connectors, etc. were used to attach the payload to the skeletal ring. The connectors had to perform at temperatures down to -60°C.